Ham filling machine

Ham filling machine

HAMLER 720 is the best suitable machine without parallel in the world to stuff fibrous casings or stuff nets in order to produce loin ham or boneless ham.

|

| |||

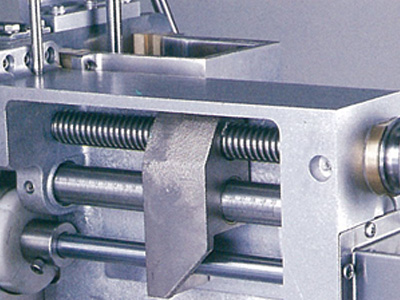

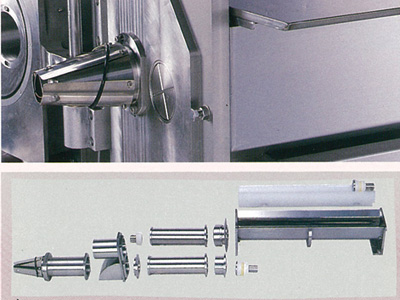

· Safe for operators Power saved design · Charge the material meat into the opening in the picture above. The maximum length of material | · Operator Friendly Design · The adjustment of material meat length can be | |||

|

| |||

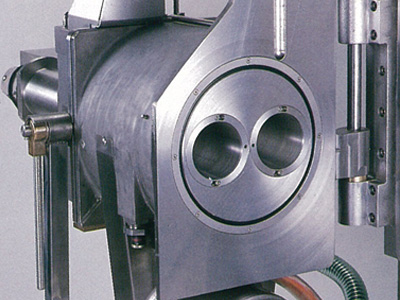

· High Yeild Rate · After the material meat formed with the moulds | · High Durobility Easy Maintenance · Supply side In drum (right in the picture) Material meat cut in a certain length come to the drum at the discharge side (at the left side in the picture) |

■ WEIGHING DRUM STUFFING RANGE ( Meat Ratio1.1 Drum Length 80-300 )

Diameter mm Min.g~Max.g

55 210~780

65 290~1100

75 390~1460

85 500~1870

95 620~2340

Stuffing Speed 20pieces/min.;With function of removing of end meat,16 pieces/min

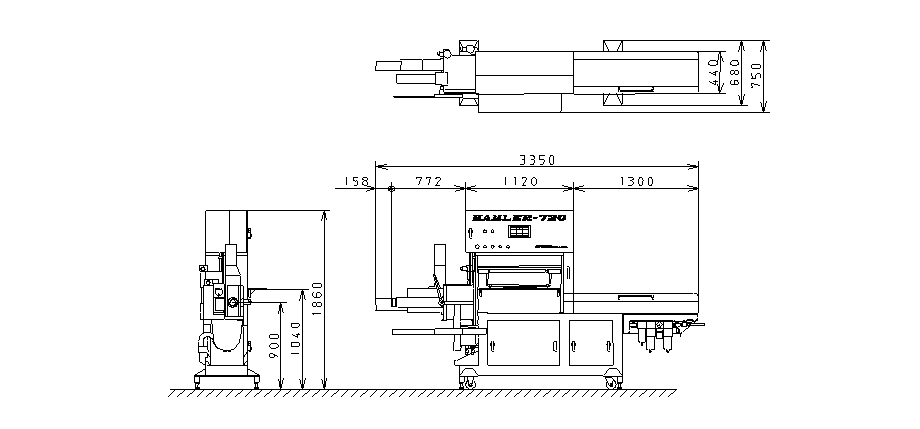

■ SPECIFICATION

Height 1860mm

Width 750mm

Length 3350mm

Weight 1000kg

Power Requirements Single Phase 100V 500W

Pneumatic Requirements 7kg/cm2 ;Compressor Conversion 11kW 15Horsepower

※ Specifications and equipment are subject to change without any obligation on the part of manufacturer.

※ The above production rate is subject to change due to the conditions such as production item, factory and other conditions.

■ LAYOUT